Advanced Process Expert for Multi-Pressure ALD/CVD and Etch

Minimize Scrap and Maximize Yield in Real Time

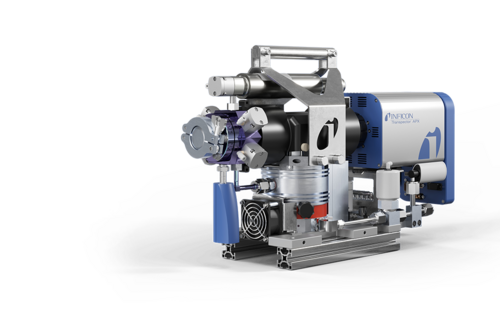

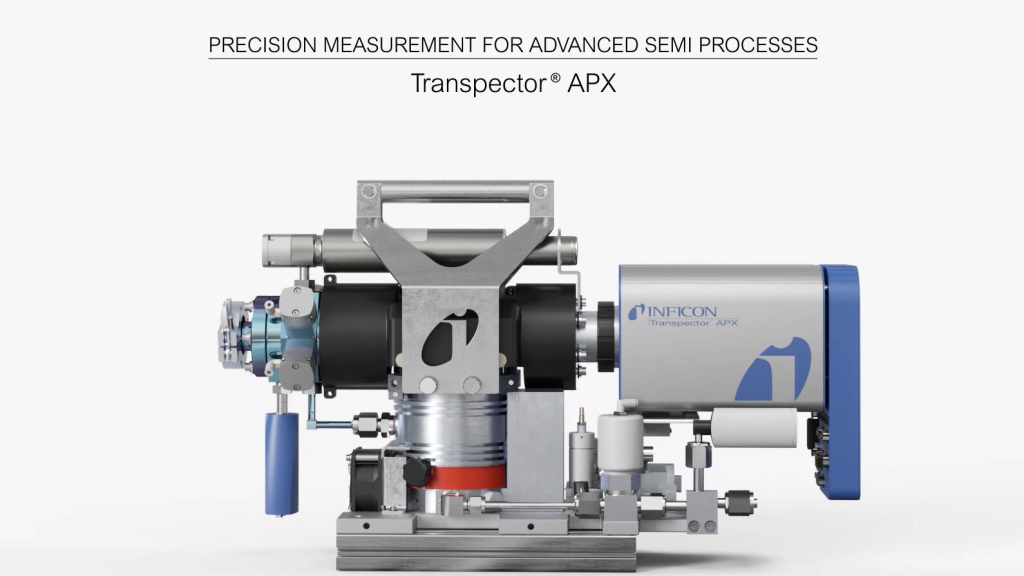

INFICON Transpector APX remains the market leading Residual Gas Analyzer (RGA) for semiconductor and display process monitoring. INFICON knows semiconductor and display customers have unique needs, and the latest revision of the Transpector APX allows for more flexibility to meet specific application requirements, while maintaining industry leading measurement speed and sensitivity. Transpector APX is the ideal RGA process monitor for semiconductor processes such as ALD, CVD, PVD, and Etch.

The next generation Transpector APX Multi-Pressure inlet system is designed to survive process chemistries prone to particle or coating generation like ALD or PECVD. This allows for continuous monitoring to capture data points at all critical process steps. In addition the HexBlock inlet is available with INFICON proprietary coating for resistance to corrosive gases, essential for chamber clean endpoint monitoring applications.

Advantages

- Application specific platform design for longest lifetime on your ALD or CVD process for the best wafer and panel protection and process optimization

- ALD ready with measurement speeds of over 550 data points per second

- Reduced fab footprint by 30% and easier installation due ne high performance pumping system

- Configurable HexBlock™ with INFICON proprietary coating with up to three pressure inlets that can withstand harsh corrosive chemistry

- Automated calibration ensures long-term data reliability and accuracy for sensor to sensor and tool to tool chamber matching

- Transpector APX becomes a powerful process monitoring and diagnostics tool when integrated with FabGuard® software and supported by INFICON world-class application experts

Specifications

100 AMU

| Total Pressure Range | 5E-7 – 1E-3 Torr6.6E-7 – 1.3E-3 mbar |

| Detection Limit | <10 ppb |

| Process Pressure Range | 1E-8 Torr – 1.2 atm1.3E-8 mbar – 1.2 atm |

| Sensitivity (Low Emission) | >4.0E-6 amps/Torr>3E-6 amps/mbar |

| Sensitivity (High Emission) | >2.0E-5 amps/Torr>1.5E-5 amps/mbar |

200 AMU

| Total Pressure Range | 5E-7 – 1E-3 Torr6.6E-7 – 1.3E-3 mbar |

| Detection Limit | <25 ppb |

| Process Pressure Range | 1E-8 Torr – 1.2 atm1.3E-8 mbar – 1.2 atm |

| Sensitivity (Low Emission) | >2.0E-6 amps/Torr>1.5E-6 amps/mbar |

| Sensitivity (High Emission) | >1.0E-5 amps/Torr>7.6E-6 amps/mbar |

300 AMU

| Total Pressure Range | 5E-7 – 1E-3 Torr6.6E-7 – 1.3E-3 mbar |

| Detection Limit | <50 ppb |

| Process Pressure Range | 1E-8 Torr – 1.2 atm1.3E-8 mbar – 1.2 atm |

| Sensitivity (Low Emission) | >1.0E-6 amps/Torr>7.6E-7 amps/mbar |

| Sensitivity (High Emission) | >5.0E-6 amps/Torr>3.8E-6 amps/mbar |

Consumables

| Part Number | Description |

| 969-800-G1S | APX CIS Tungsten Filament Kit GOLD |

| 969-800-G2S | APX CIS Coated Filament Kit GOLD |

| 969-801-G1S | APX CIS Tungsten Ion Source Kit GOLD |

| 969-801-G2S | APX CIS Tungsten Ion Source Kit with Anode Liner GOLD |

| 969-801-G3S | APX CIS Coated Ion Source Kit GOLD |

| 969-801-G4S | APX CIS Coated Ion Source Kit with Anode Liner GOLD |

| 961-707-G1 | Electron Multiplier Replacement Kit |

| 923-418-G2 | Replacement diaphragm kit for 2-stage pump |