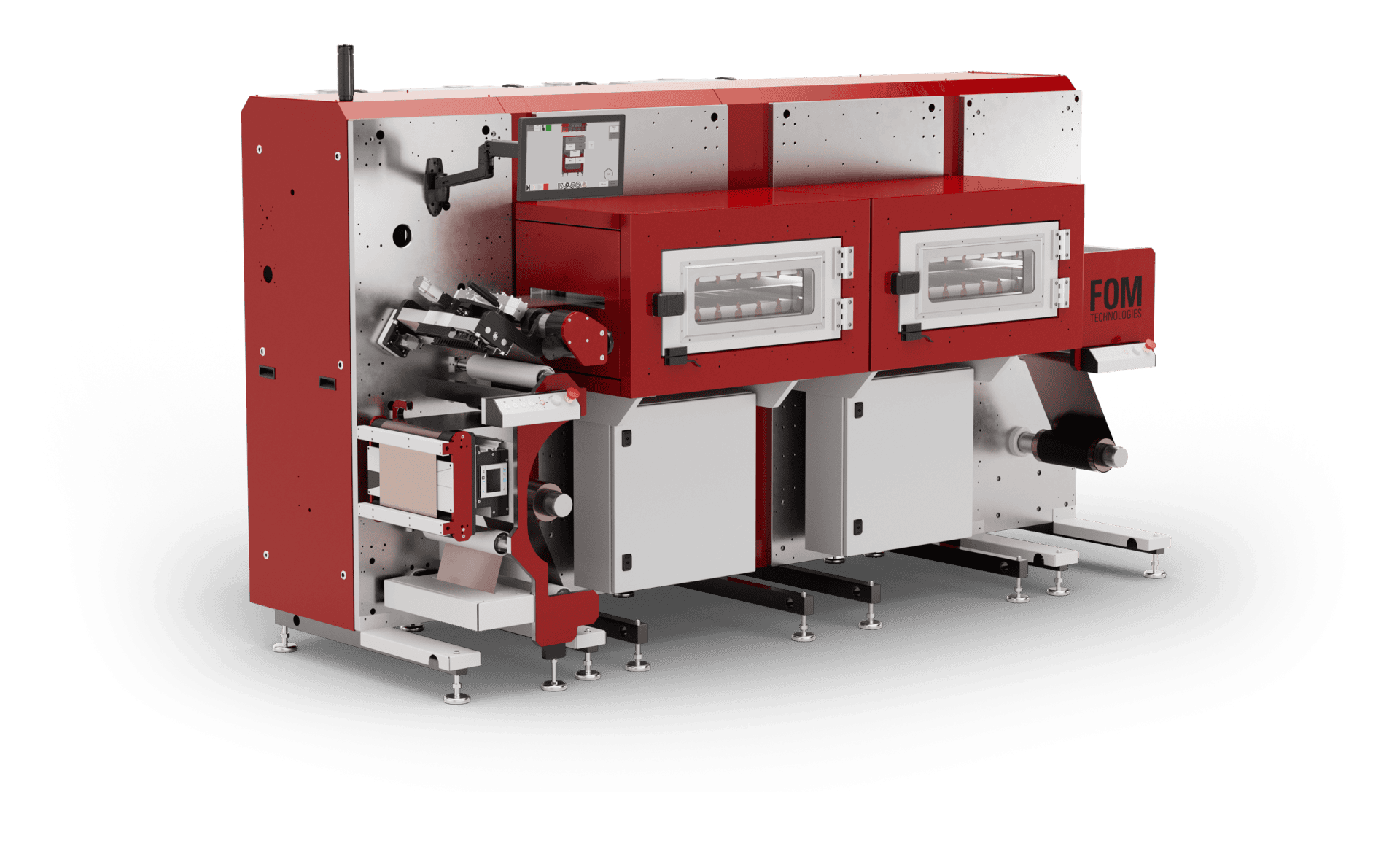

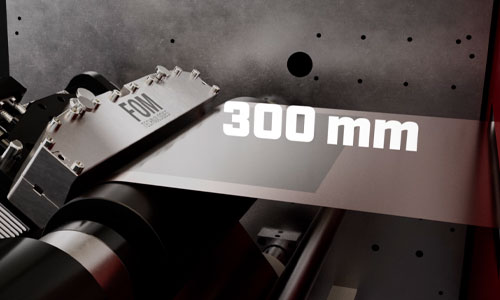

The FOM compact moduloR2R is a cost-efficient, high-throughput roll-to-roll slot-die coating system designed for pilot-scale R&D. Its modular design allows for selecting and integrating a broad range of pre- and post-coating options and metrology add-ons. This makes the compact moduloR2R ideal for slot-die coating a wide range of functional materials such as battery electrodes, fuel-cell membranes and flexible solar cells and other thin films up to 300mm in width. Furthermore, the compact moduloR2R can be expanded and adapted to future requirements as they evolve, which safeguards your investment also in the longer term.

Key features

- Roll-to-roll slot die coater with up to 300 mm coating width

- Continuous, non-contact coating process with µm precision

- Uniform and reproducible dry film thickness from nm to µm

- Motorized height and tilt adjustment of slot-die head positioning (+/- 1 µm)

- Adjustable coating angle (0-90o)

- Intuitive graphical user interface

- Advanced coating software

- Local and cloud coating protocol saving

- Compact and modular design

- Multiple drying and curing options

- Bi-directional web handling and tension control

- Convenient and easy roller replacement

- Remote support and troubleshooting

Small footprint, high throughput

Engineered for advanced research applications

Developed to meet the evolving demands of cutting-edge research, the FOM compact moduloR2R provides an adaptable and precise roll-to-roll coating platform. Designed specifically for R&D environments, it enables researchers to fine-tune process parameters, explore new materials, and achieve reproducible results without the constraints of traditional industrial systems, while supporting the deposition of functional thin films up to 300mm in width, making it an essential tool for advancing material science and scalable innovation.

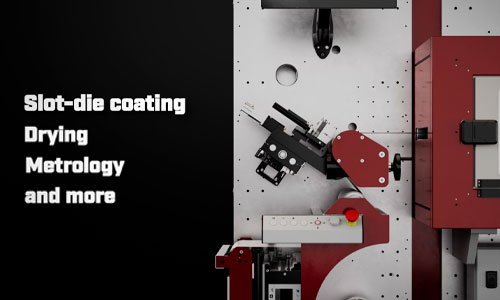

Compact and modular design

Built for versatility, the moduloR2R features a modular architecture that allows seamless integration of pre- and post-coating options, metrology tools, and flexible drying technologies. Its compact footprint ensures efficient use of lab space while providing the flexibility needed for a wide range of research and development applications.

Drying

Flexible drying options enable the user to tailor the FOM compact moduloR2R to their specific process requirements, ensuring optimal coating performance across a variety of materials. With support for air knife, infrared (IR), ultraviolet (UV), and advanced air floatation oven drying, the system offers versatility to accommodate diverse research and production needs. Whether adjusting for different drying temperatures, airflow conditions, or curing times, these customizable options provide enhanced control, consistency, and adaptability to meet the unique demands of research and production environments.

Comprehensive software

Equipped with an extensive coating parameter, drying options and Ethernet connectivity, the FOM compact moduloR2R ensures easy maintenance and offers remote service capabilities, providing efficient support for uninterrupted operation.

Adaptable for pilot-scale production

The FOM compact moduloR2R is built for scalability. Leveraging an advanced PLC platform, the system is Industry 4.0 ready, allowing seamless reconfiguration when transitioning research into pilot scale.

Watch the full video

for MORE INFORMATION

Applications

or CONTACT US