High-quality roll-to-roll machines

Advanced level

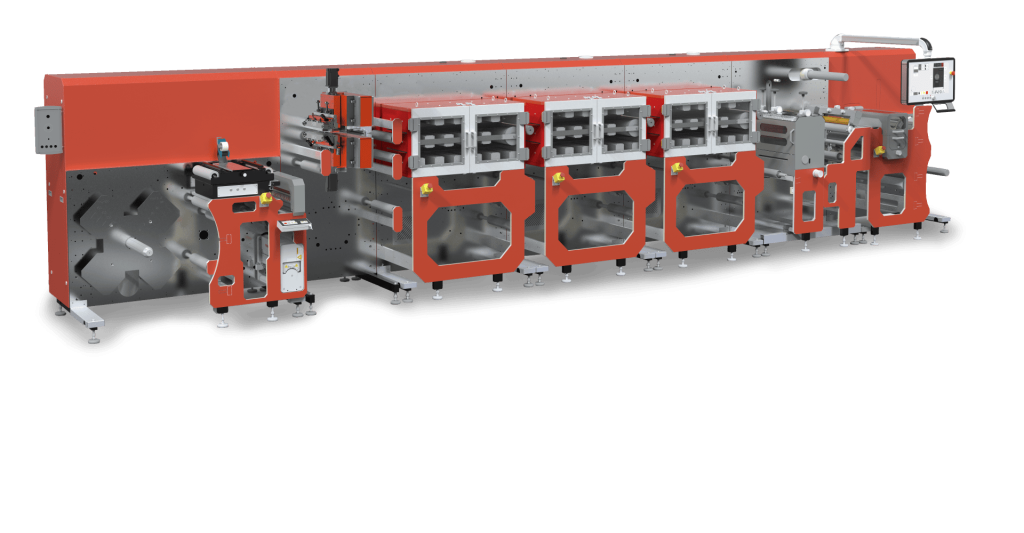

The FOM moduloR2R is a highly capable, modular roll-to-roll pilot line platform. The base model consists of unwind, rewind, oven, and slot die stations for simple pilot-scale thin film production. This can be easily customized and optimized for a given coating process by adding various machine modules and process stations. The FOM moduloR2R makes designing the perfect production line for a particular process simple, representing an ideal first step from R&D to full-scale production.

Designed for experimental research

The FOM moduloR2R addresses the challenges associated with roll-to-roll equipment in R&D environments. Industrial roll-to-roll equipment often lacks the necessary freedom to experiment, adapt and data collect as is common in research.

Easy operation

To accommodate the flow of the research process the FOM moduloR2R provides a flexible system that allows facile experimental set-up, data collection, and operation.

Modular built

The modular-built FOM moduloR2R is fitted with all-around web access for easy maintenance and constant monitoring of the printed web. Furthermore, the FOM moduloR2R enables custom configuration and positioning of the coating, printing, and drying units ideal for R&D. Upon request, the FOM moduloR2R is Atex-compatible with certification.

Digital control and data collection

The coater is based on a digitally controlled platform and provides process control and complete process data logging with export functions to enable researchers to analyze this data.

Data management

Automated documentation is key to handle large data volumes. The complete coating conditions are automatically logged by the control software and can also be printed alongside the coated area by a synchronized barcode printer/reader.

Coating & printing methods

The FOM moduloR2R facilitates the integration of multiple coating and printing methods into the machine frame, for example, slot-die coating and flexographic, inkjet, or rotary screen printing. In principle, any deposition method can be integrated. Designed to handle a wide range of substrates it is currently running with carbon fiber tows, multiple plastics, paper, metal foils, and flexible glass.

Software

The integrated, extensive, and self-diagnostic monitoring system with Ethernet access provides easy service support and offers remote service as well as maintenance supervision.

Inbuilt industrial reconfiguration

The FOM moduloR2R is capable of industrial production speed. Based on a new PLC platform the machine is Industry 4.0 ready. This allows facile reconfiguration for industrial production once your research is ready for technology transfer to a pilot or commercial phase.

Key features

- Roll-to-roll slot die coater

- Continuous, non-contact coating process

- Coating with µm precision

- Uniform dry film thickness from nm to µm

- Adjustable slot-die head contact angle

- Double-sided coating

- Double and single ovens

- Automated coating via intuitive GUI

- Remote access from PC or Tablet

- Local and cloud coating protocol saving

- Modular design for optimized process

- Integrated pump with SW controlled wet film thickness

- Designed for flexible substrates

- Two directional wind and unwind capability

- Full web, tension via servo-controlled system

- Convenient and easy roller replacement

- Excellent layer uniformity, and repeatability

- Alignment of multiple layers

- Remote support and troubleshooting

Technical specifications

FOM moduloR2R 300

- Dimensions: 800–1600 mm x 1290 mm x 1800 mm (L x W x H) per module

- Weight: 300-800 kg per module

- Substrate roller width: Max 350 mm

- Substrate width: Max 350 mm

- Integrated PLC control system

- Intuitive HMI touch panel interface

- Fully motorized x-y-z positioning (1 µm precision)

Coating

- Coating width: up to 300 mm

- Substrate roll diameter: max 700 mm

- Coating speed range: up to 20 m min-1

- Slot-die compatibility: FOM SD 25 – FOM SD 300

Technical specifications

FOM moduloR2R 500

- Dimensions: 800–1600 mm x Approx. 1500 mm x 2000 mm (L x W x H) per module

- Weight: 300-800 kg per module

- Substrate roller width: Max 550 mm

- Substrate width: Max 550 mm

- Integrated PLC control system

- Intuitive HMI touch panel interface

- Fully motorized x-y-z positioning (1 µm precision)

Coating

- Coating width: 1 mm to 500 mm

- Substrate roll diameter: max 700 mm

- Coating speed range: up to 20 m min-1

- Slot-die compatibility: FOM SD 25 – FOM SD 500

for MORE INFORMATION

Applications

or CONTACT US