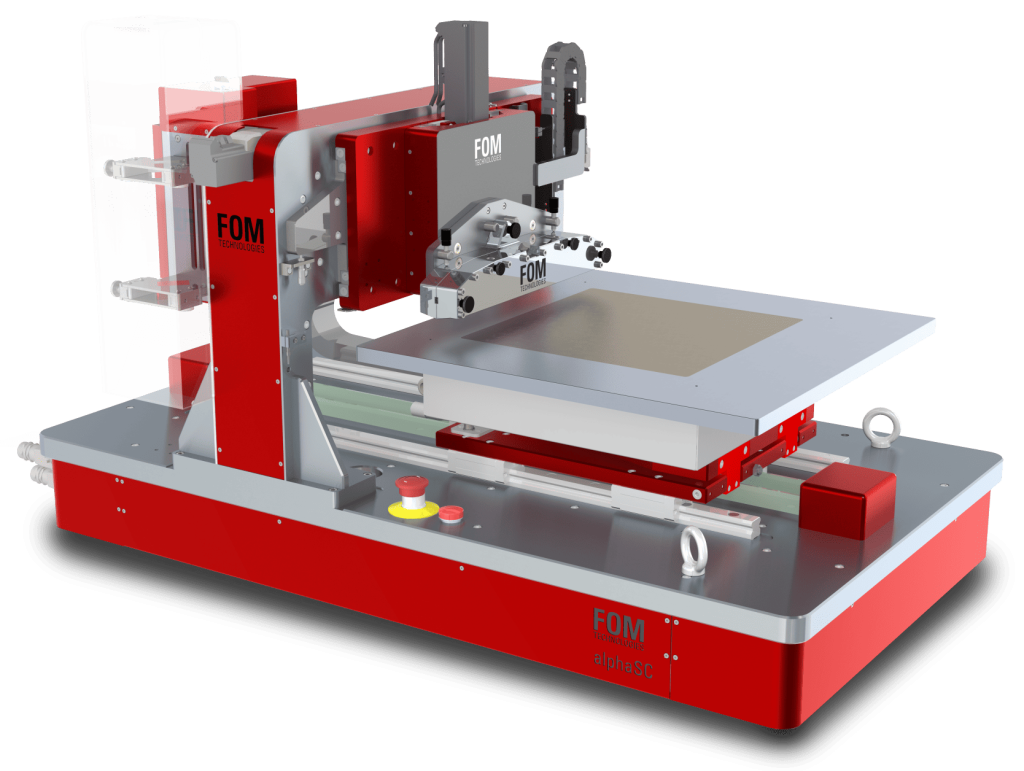

High-quality sheet-based machine

Advanced-level

The FOM alphaSC represents the ultimate combination of control, functionality, and versatility in thin-film research and production. All its hardware, software, and premium features have been tailored to eliminate experimental error and increase usability with flexible and rigid substrates. The FOM alphaSC provides users with unmatched versatility, precision, and process reproducibility for a broad spectrum of lab-scale materials and coating processes relevant to industry and academia.

Key features

- Non-contact coating within µm precision

- Uniform dry film thickness from nm to µm

- Coating width from 1 mm to 500 mm

- Microporous vacuum Substrate holder

- Automated coating via intuitive GUI

- Remote access from PC or Tablet

- Coating protocol saving in cloud

- Quick action buttons

- Integrated Pump with SW controlled wet film thickness

- Designed for rigid and flexible substrates

- Advanced heating and slot-die head positioning

- Designed for fluids up to 20,000 cPs

- Built-in hotplate for drying

- Simple scaling from sheet coating to R2R coating

- Excellent layer uniformity and repeatability

- Seamless fume hood and glove box integration

- Remote support & troubleshooting

- Roll-to-roll via docking station

Technical specification

- Dimensions: 1297 x 788 x 786 mm (L x W x H)

- Weight: 166 kg

- Substrate holder dimensions: 520 mm x 500 mm

- Substrate holder heating: Up to 200 oC

- Microporous vacuum dimensions: 305 mm x 305 mm

- Recommended cable clearance: 200 mm

- Integrated syringe pump from 1 ml to 300 ml

- Integrated PLC control system

Coating

- Fully motorized x-y-z positioning 1 µm precision

- Coating width: 1 mm to 500 mm

- Coating length: Up to 470 mm

- Coating speed: 0.01 up to 5.0 m min-1

- Slot-die head heating: Up to 80 °C

- Slot-die compatibility: FOM SD 25 – FOM SD 500

Design

The FOM alphaSC is the gold standard for world-class research centers with ambitious technology development roadmaps. A combination of full automation and seamless control software integration is the design focus that will enable unparallel reproducibility for a systematic experimental design.

Flowless automation and lab-to-fab approach.

Whether you are doing fundamental research, developing next-generation concepts or aiming to produce record efficiencies, the FOM alphaSC is equipped to accelerate your development regardless you are focusing on rigid or lightweight flexible substrates. The incorporation of a microporous substrate holder will provide homogeneous suction avoiding extra steps that are typically done to fixate the sample into the substrate. Together with the software integrated pump, and the automated vertical and lateral movement of the slot-die head, the FOM alphaSC will allow for high throughput, highly systematic experimental design with an accelerated workflow. Post-deposition treatments units such as drying/annealing, compressed gas for quick-drying and docking modules can be added to the stand-alone FOM alphaSC tool to become a small scale pilot processing line. The FOM alphaSC tool is well equipped for boosting the technology readiness level of your research, and demonstrating proof of concepts from lab to fab.

Reproducibility and high precision

The software features the possibility for the generation of a protocol library allowing to call back and reproduce a deposition process with high precision giving the researcher an insight into the variables of the coating process.

for MORE INFORMATION

Applications

or CONTACT US