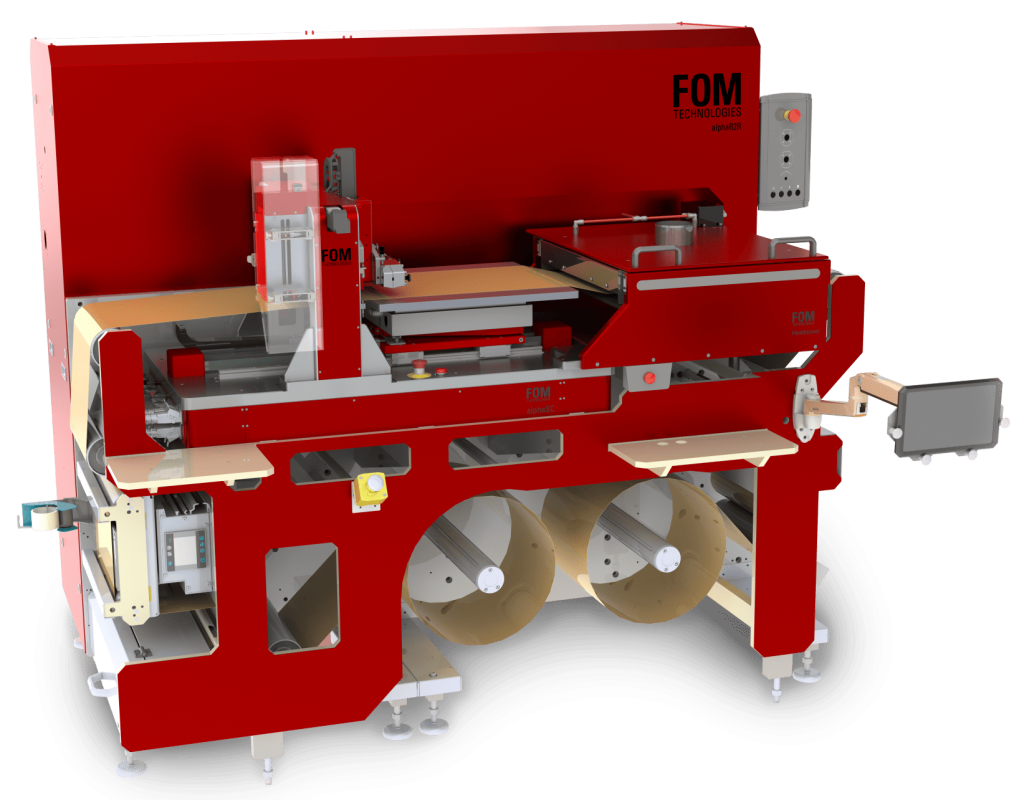

High-quality sheet-based machine

Advanced level

The FOM alphaR2R represents a cutting-edge research and production sheet-to-sheet coating machine equipped with seamless roll-to-roll capability. This system redefines control, functionality, and versatility. FOM alphaR2R is tailored to eliminate experimental errors and enhance usability with flexible and rigid substrates, offering unmatched precision and reproducibility. Whether in academia or industry, this machine easily empowers lab-scale research and production processes.

Key features

- Sheet-based & roll-to-roll slot die coater

- Coating within µm precision

- Uniform dry film thickness from nm to µm

- Microporous vacuum substrate holder with heating

- Automated coating via intuitive GUI

- Remote access from PC or tablet

- Coating protocol saving locally and in cloud

- Continuous, non-contact coating process

- Quick action buttons for frequent tasks

- Integrated pump with SW controlled wet film thickness

- Designed for rigid and flexible substrates

- Two directional wind and unwind capability

- Full web and tension via servo-controlled system

- Convenient and easy roller replacement

- Excellent layer uniformity and repeatability

- Alignment of multiple layers

- Remote support and troubleshooting

Technical specifications

- Dimensions: 2400 x 1550 x 1820 mm (L x W x H)

- Weight: 1450 kg

- Substrate holder dimensions: 520 mm x 500 mm

- Substrate holder heating: Up to 200 °C

- Substrate roller width: 400 mm

- Substrate width: max 350 mm

- Microporous vacuum dimensions: 305 mm x 305 mm

- Microporous vacuum on the sheet-coated area

- Web guide: Automatic

- 3-inch pneumatic mandrels

- Advanced coating automation software

- Cloud-compatible protocol saving

- Integrated syringe pump from 1 ml to 300 ml

- Integrated PLC control system

- Fully motorized x-y-z positioning (1 µm precision)

for MORE INFORMATION

Applications

or CONTACT US