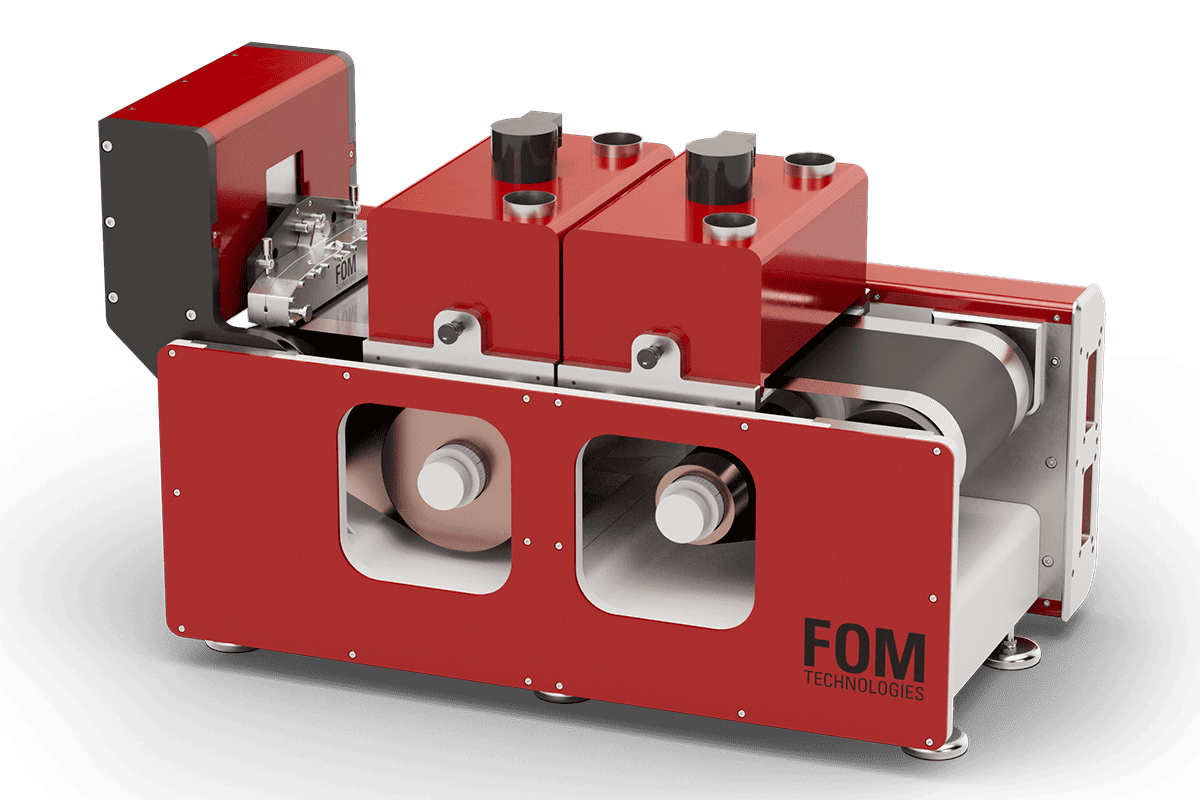

FOM omicronR2R is a high-precision, lab-scale roll-to-roll slot-die coater, meticulously engineered to meet the rigorous demands of advanced materials R&D. Designed for seamless integration into gloveboxes and fume hoods, the system enables safe, stable, and repeatable coating operations in controlled environments—ideal for processing air- or moisture-sensitive materials.

The machine is backed by FOM’s end-to-end application support, which includes expert installation, onboarding, and continuous process development guidance. This ensures researchers get the most out of their system from day one.

Compact and glove box compatible

Modular architecture

FOM omicronR2R features a fully modular system architecture, allowing you to reconfigure the drying section to meet specific material and process needs. Whether your work requires infrared curing, UV activation, or traditional hot air drying, the system’s oven modules can be arranged and extended as your research evolves.

Advanced coating control software

The platform includes a user-friendly, cloud-connected control interface that simplifies recipe creation, process logging, and repeatability. With full control over coating speed, drying parameters, and substrate movement, researchers can easily fine-tune experiments and share protocols across teams.

Precision coating technology

Combined with a motorized slot-die head capable of coating up to 200 mm in width, the system enables reproducible deposition of films from nano- to microscale thicknesses. This integration of digital control and mechanical precision makes it an ideal platform for material screening, data consistency, and process optimization.

Watch the full video

More about FOM omicronR2R

Explore full specifications, application areas, and support services. Learn how FOM omicronR2R can accelerate your research—from formulation to thin-film process refinement. Download the data sheet and get in touch with our sales experts.

Need help select or design your suitable machine!