Seal Testing for Food and Pharma Packages

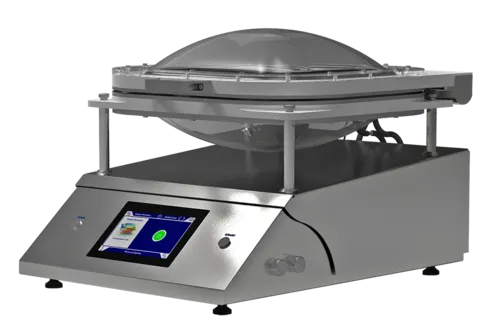

The innovative Contura S400 and S600 leak detectors offer manufacturers of packaging machines, food and Pharma industry, in general, a unique solution for seal inspection in Capsules, MAP- and other types of packaging in accordance with DIN EN 1779 and in close resemblance to ASTM F2338-09.

Unless other solutions it can detect gross leaks as well as fine leaks which are undetectable by the naked eye or by the water bath method (also known as “bubble test”). The unique technology of Contura S-Series can detect any leak (not only seal damage) without the need for tracer gas and at the same time without damage to the package.

Package Integrity DIN EN 1779

Operating this seal tester is also simple and accurate. The flexible test chamber consists of two highly elastic membranes. By creating a vacuum, these membranes tightly enclose the tested package. The leak detector analyzes the pressure increase in a few seconds. Contura S-Series Seal Tester can then detect even the smallest leaks rapidly and reliably.

Advantages

- Even small leaks (size < 10 μm) can be detected in seconds

- Detection of gross leaks even in packages with little headspace

- Immediate display of seal testing results

- Storage and evaluation of seal testing results

- Designed according to DIN ISO certified documented output inspection

- Large touchscreen display

- Testing of individual or multiple packages

- Mobile stand-alone solution for different seal testing applications in a variety of production lines

- Electronic operation requires no compressed air

- Simple and safe cleaning to meet the strict hygiene requirements of the food industry

Typical Applications

Quality assurance/seal inspection/checks

- For seal testing of food and Pharma packaging

- Allows Food manufacturers to check if newly delivered packaging machines produce tight packaging

Brochures & Data Sheets

Related Products

Sensistor® Sentrac® Hydrogen Leak Detector

Sensistor® XRS9012 Hydrogen Leak Detector