Making Excellence Repeatable

Protect and Grow Your Profit with Precision Rate and Thickness Monitoring

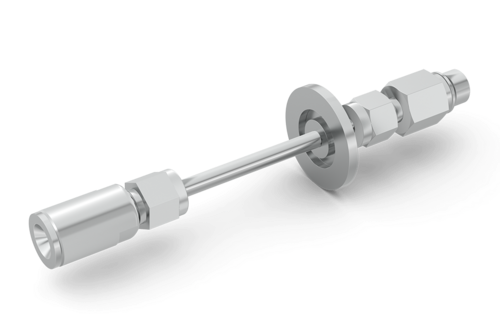

The SemiQCM™ CR sensor is a chemically inert sensor that can be installed in some of the harshest CVD or ALD chambers. SemiQCM CR is one component of a system for precursor monitoring with the other components being an IMM-200 and FabGuard (version 19.12.00-a or higher).

Semi Process Monitoring can be used in semiconductor applications for end point detection and fault elimination by monitoring the amount of precursor in the foreline or chamber exhaust. The use of an in situ QCM provides affordable process monitoring and improved semiconductor process profitability.

The failure to deliver precursor to a wafer can be detected in as little as one wafer.

Features

- QCM data monitored at 10Hz

- FabGuard correlates QCM data to tool state and process step

- Precise measurement of deposition or etch rates

- Sensitivity & precision for sub-monolayer thickness measurement

Advantages

- Real-Time, in situ process monitoring

- Prevent over-etching, identify chamber clean end point

- Identify equipment or process state fault

Typical Applications

- Semiconductor Manufacturing